MES and SCADA

SCADA stands for Supervisory Control And Data Acquisition. The core of a SCADA systems consists of a Graphical User Interface allowing process operators to see what is happening within their plant and make changes to equipment and process settings to maintain and where possible improve production and safety levels. In comparison, the core of a MES system focuses on managing, tracking, controlling, documenting and improving manufacturing work on a factory floor. SCADA systems may have been extended to overlap MES core functions. In such SCADA systems, equipment data is acquired in real-time and stored at a granular level and the User Interface contains a range of functions allowing the tracking of production processes, products and equipment use. On the other side, MES systems sometimes contain custom extensions to show within a User Interface of the MES, in real-time, SCADA type of visualizations of production units. MES and SCADA can be used seperatly or in conjunction with each other.

Symbiotic relationship between MES and SCADA systems

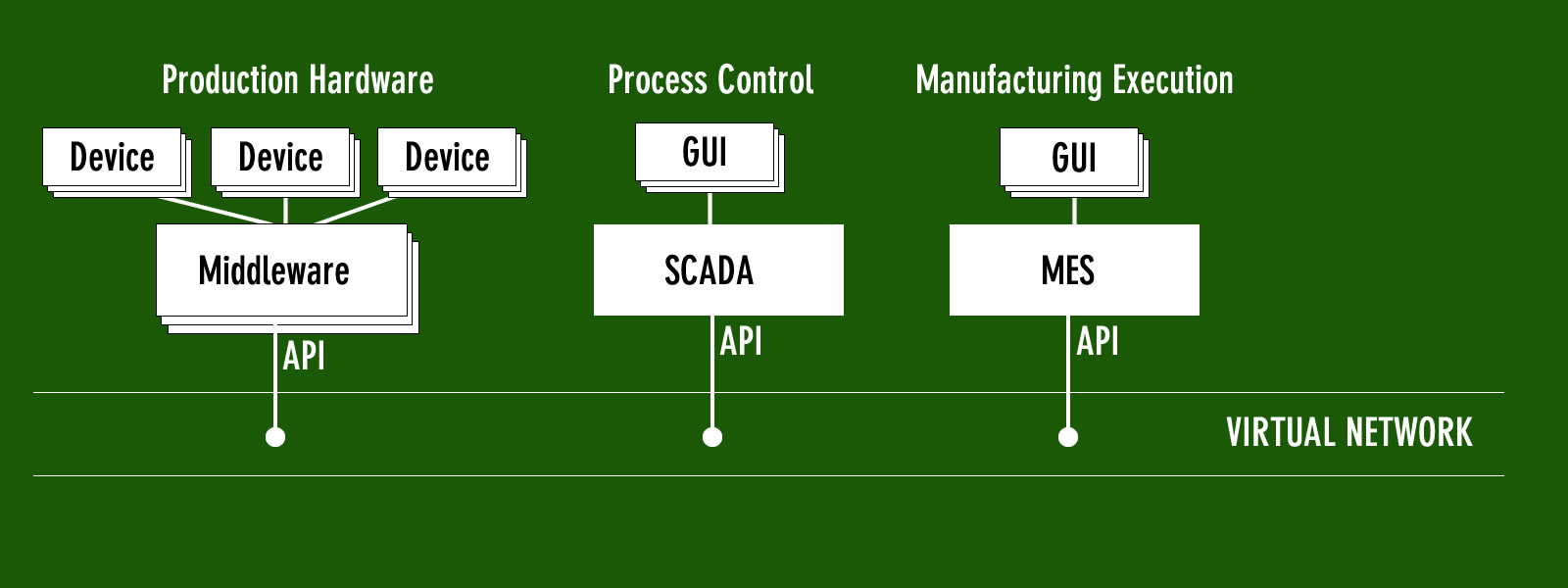

Both SCADA systems that have been extended with MES functionality, as well, MES that has integrated some kind of SCADA functionality will in all cases be a kind of a compromise. While in some cases, choosing either a SCADA or a MES may be a great solution, it becomes increasingly easier to use the best of both worlds. Main reason, modern SCADA and MES are much more open and interconnectable than they used to be, offering open API's and Webhooks. An open API provides a standardized way to connect two software systems with each other and to request, exchange and send data in real-time. Webhooks allow one system to actively notify another system that a task or process had been completed or that an exception or alarm has been raised.

Role of MIDDLEWARE

Industrial devices that allow access and control via a network interface, often use proprietary/legacy protocols. Resulting in a very heterogeneous landscape where it can be difficult to connect all these devices via a network to each other and to other systems. Middleware systems are likely the best solution to make this heterogeneous landscape more manageable. They provide the means to access, control and query existing devices via standardized mechanism and protocols. To make this possible, Middleware systems contain a large collection of libraries and configurable plugins for "plug-and-play" connections to all industrial devices of popular brands. In such a setup, both a SCADA and MES does not connect directly to a specific device but does this so via the Middleware systems. Although, in some cases, a SCADA system may still need some propriate/legacy connections to some devices for, for example, safety reasons. The MES samples production process data by querying the SCADA systems via its API and by querying the devices used by production flows via the Middleware API. In addition, both the MES and the SCADA system can receive messages from the Middleware, triggered by devices, such as alarms or state changes. In case a Private Cloud is in place, the carrier of the Enterprise Communication Bus would be the Virtual Network over the Internet.

EZ-MES and SCADA

EZ-MES is a real-time browser based Manufacturing Execution System that can run both on premises as well within a Virtual Private Network and make use of Cloud Computing. EZ-MES comes with an Open API and Webhooks allowing it to connect to other systems and devices. It is possible to connect EZ-MES to SCADA systems that allow data access via an API.

The following video demonstrates the use of the EZ-MES API to interface over a Private Network with a SCADA system. in this case, Node-RED is used as a Middleware layer. By doing so, EZ-MES can be used to fully track equipment measurements in production processes. In this demonstration, EZ-MES is used to track an Oven temperature via Node-RED during a simplified production process.